The zirconia implant

The proven two-piece implant system made of high-performance ceramics (ATZ) - Made in Switzerland. In clinical use since 2017

Zeramex XT surgery

General

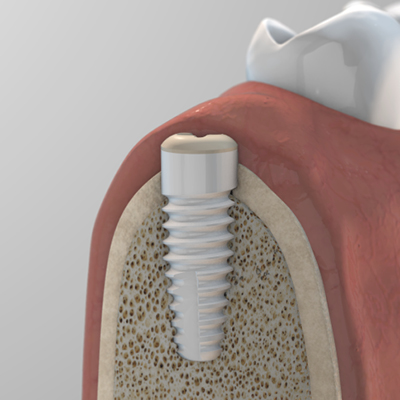

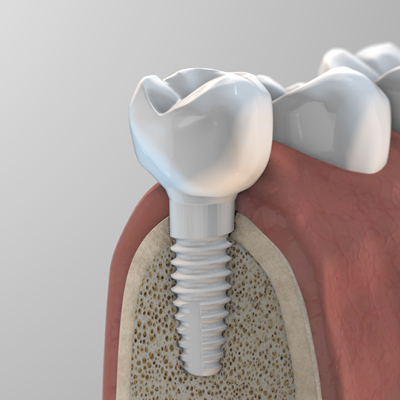

The Zeramex XT dental implant belongs to the family of two-piece and 100% metal-free Zeramex ceramic implants*. It offers maximum prosthetic flexibility, thanks to reversible screw-in connection and an unlimited range - particularly in the anterior area.

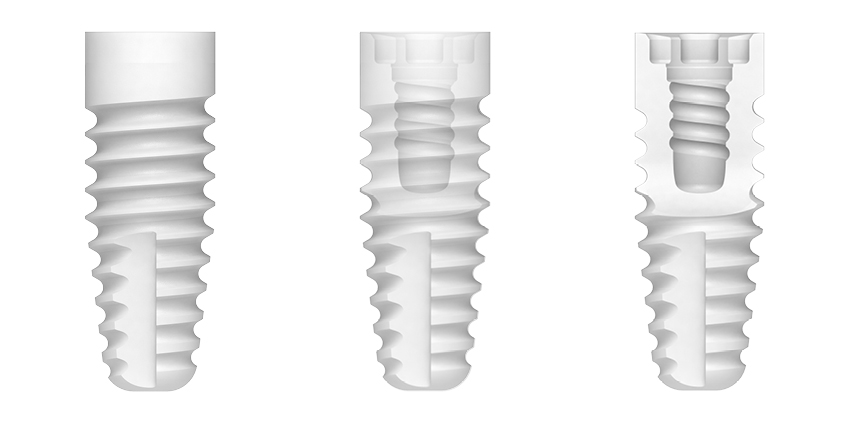

Implants

The Zeramex XT ceramic dental implant offers three different platforms (SB / RB / WB) in lengths of 8, 10, 12 and 14 mm and is particularly suitable for anterior restorations, thanks to its small diameter and digital workflow.

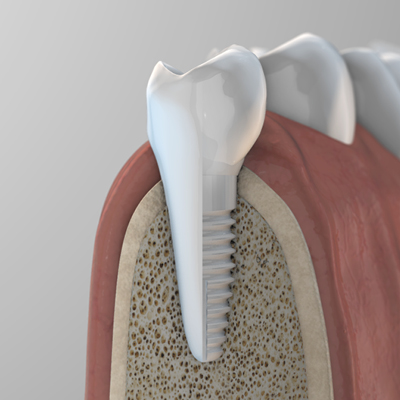

The Zeramex XT ceramic implant is placed 1.6 mm supracrestal but can optionally be placed deeper (up to 0.6 mm supracrestal). The cylindrical-conical design of the implant thread was developed to achieve high primary stability. The reservoir for bone grafts at the implant tip simplifies the placement of the implant.

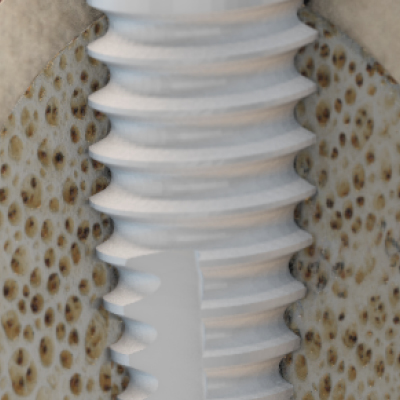

Manufacturing

The Zeramex XT ceramic implant is manufactured from hard zirconium oxide ATZ blanks manufactured by hot isostatic pressing. No thermal sintering or post-processing takes place after the final shaping of the outer and inner geometry of the dental implant. This ensures that no further changes can occur in the material structure. This manufacturing process is very complex, requires a great deal of experience and expertise and enables a high shaping accuracy and precision in the manufacture of the ceramic implant.

Do you require any further information regarding the Zeramex XT ceramic implant system? Click here for the user instructions:

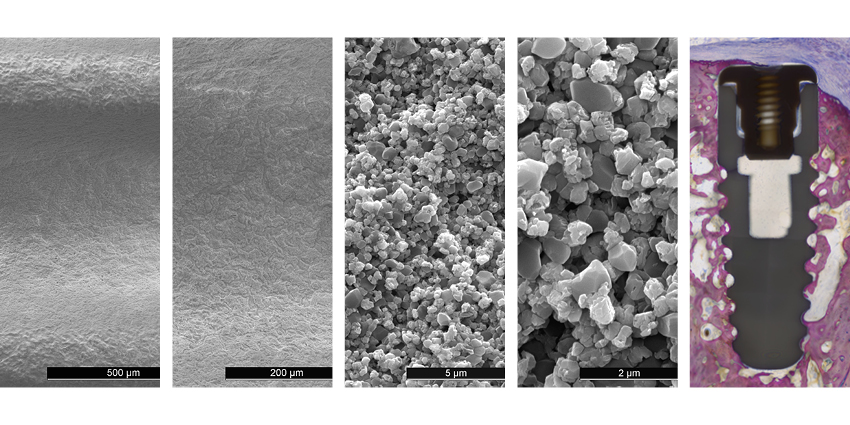

Surface

The Zerafil surface is a micro-structured implant surface that enables decisive osseointegration of the dental implants.

The success rate for the Zeramex XT ceramic dental implants used with the Zerafil surface is 98%, and bears witness to the decisive osseointegration thanks to an optimum surface structure.The hydrophilic implant surface Zerafil (surface treatment up to a collar height of 0.6 mm) is sandblasted and etched so that osteoblasts can grow directly up to the dental implant and firm adhesion to the implant surface can be achieved4.

Clinical application of zirconia implants: Results from comparative studies, Dr Elisabeth Jacobi-Gresser

Zeramex XT connection

«Bolt-In-Tube» internal connection

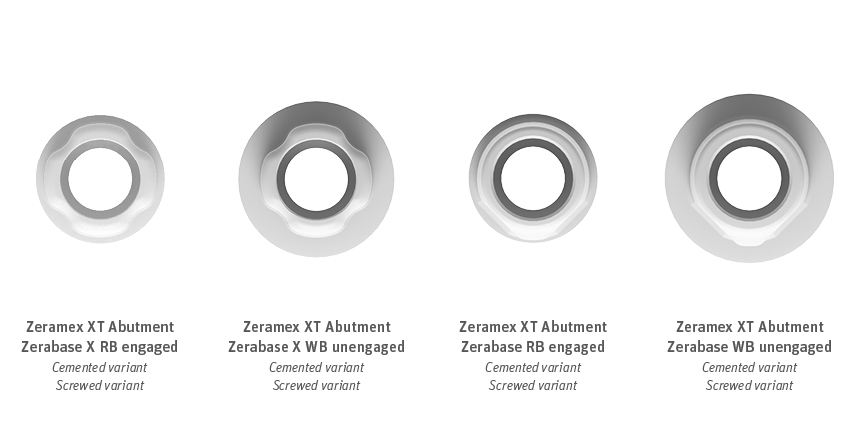

The four cross-shaped retentive elements provide an ideal transmission of torque when inserting the ceramic dental implant and allow the implants to be screwed into the bone without stress peaks. This unique internal connection ensures a precise and prosthetically flexible restoration.

Four tips for even more precision

The special geometry with the four tips enables high precision and fast and easy insertion and alignment of the abutment. All abutments are designed with the four tips, including the Zerabase and 'unengaged' Zerabase X abutments for bridge restorations.

Vicarbo technology

The core of the connection is the Vicarbo screw.

It works like a bolt, which anchors the abutment in the implant. The extremely hard ceramic is combined with a very stiff, carbon fibre-reinforced high-performance PEEK polymer. Similar to reinforced concrete, the ceramic absorbs the compressive forces, while the Vicarbo screw counteracts tensile forces.

Zeramex XT prosthetics

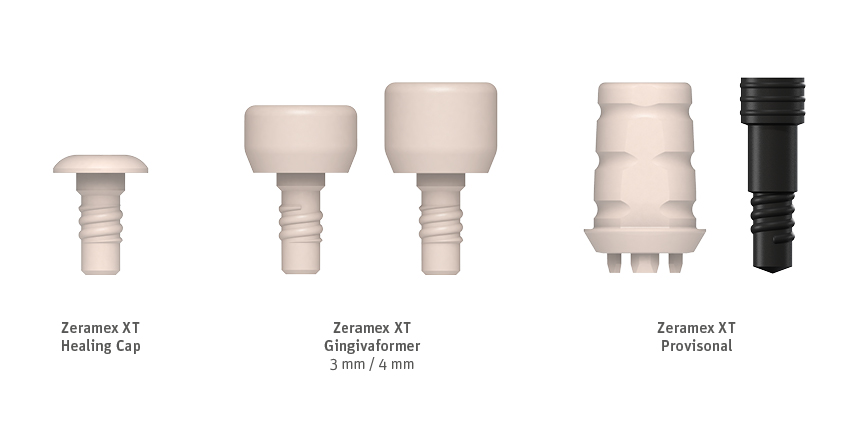

Soft Tissue Management

The Zeramex healing cap, gingiva former and temporary abutment help to achieve the desired shape of the peri-implant soft tissue after the healing phase.

The gingiva formers are available in two heights (3 mm/4 mm). The secondary temporary abutment made of PEEK allows individual temporary restoration.

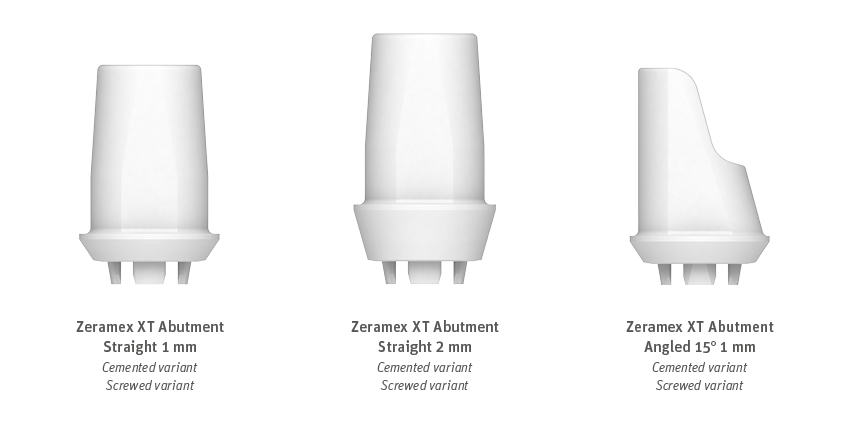

Restoration - standard

The range of metal-free prosthetics is extensive and satisfies the stringent requirements with regard to aesthetics and functionality. The Zeramex XT ceramic implant, in combination with its various standard abutments, is ideal for nearly every situation.

The standard abutments are available for all three platforms (SB / RB / WB) with different shoulder heights and angles.

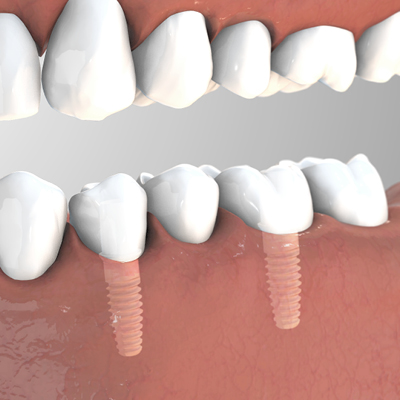

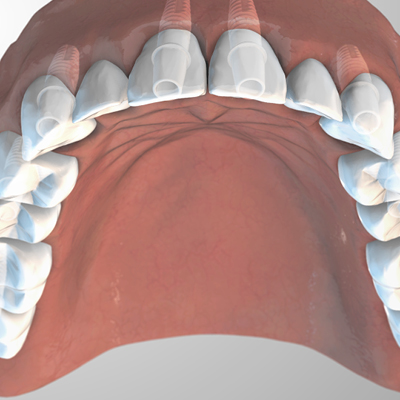

The Zeramex XT ceramic implant system is used for the following indications:

- Individual tooth restorations

- Bridge restoration using several ceramic implants

- Bar restoration using several ceramic implants

- Removable restoration in combination with Zermex Docklocs® abutments

- Telescopic restorations

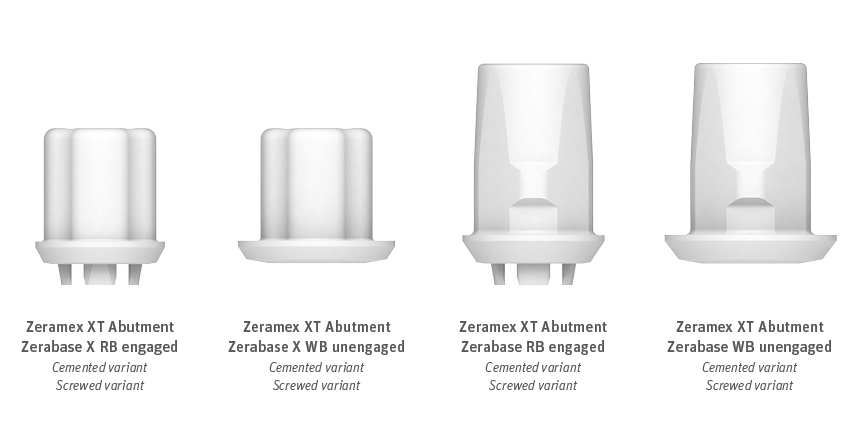

Restoration - adhesive base

Monolithic crowns and bridges can be made of various optimised plastics or zirconium oxide. By contrast, classic all-ceramic crowns and bridges are made of layering or pressed ceramic on a zirconium oxide cap.

Different Zerabase X abutments and a digital workflow make it possible to find the correct abutment in every case for an aesthetically demanding, 100% metal-free restoration.

Zerabase X: The CADCAM alternative for laboratory and chairside

- Shorter and more elegant design

- Also enables larger angulations

- Available for (SB / RB / WB)

- Variable adjustment (engaged/unengaged)

- Digital impression possible with Scanbody

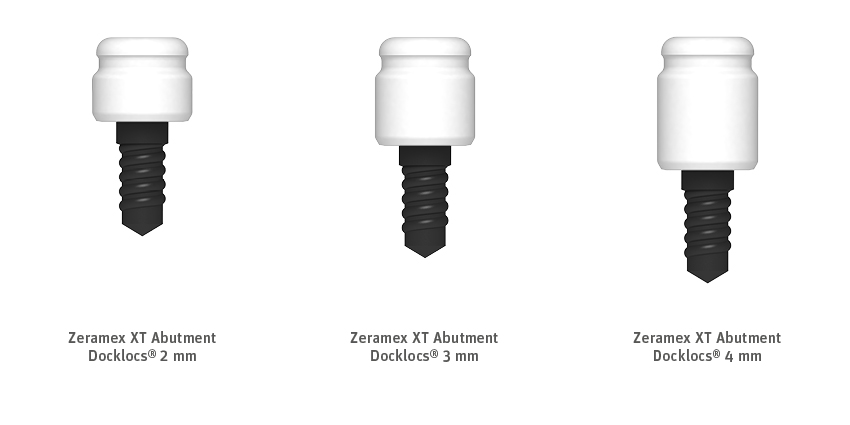

Restoration - Docklocs®

Zeramex Docklocs® is a pre-finished connection system to secure removable restorations based on a snap connection.

Zeramex Docklocs® abutments are available in three sizes (2 mm/3 mm/4 mm) and fit to all platforms (SB/RB/WB).

*Proof of conformity of Zeramex products can be found at ifu.zeramex.com.

References

Docklocs® is a registered trademark of MEDEALIS GmbH, Germany.

Do you have any questions?

Please do not hesitate to contact us for further information regarding the Zeramex XT implant system.